- Home

- Products

- Industries

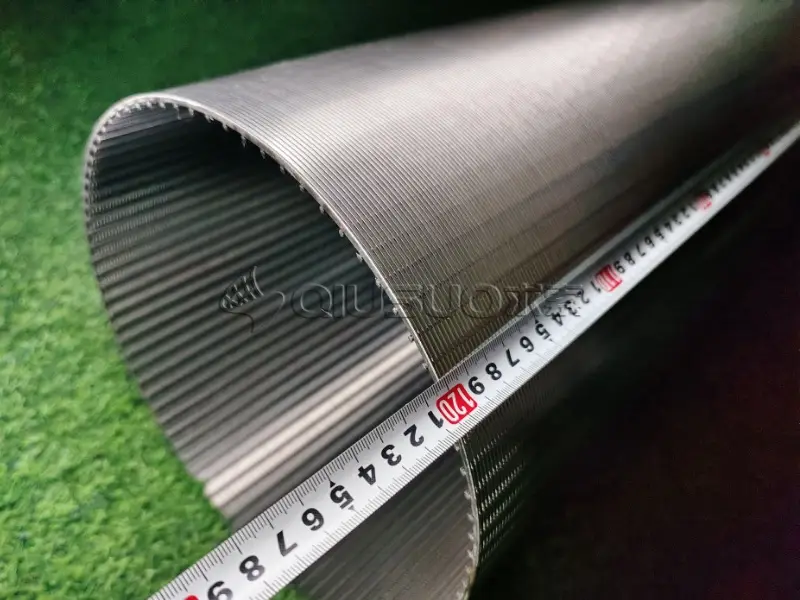

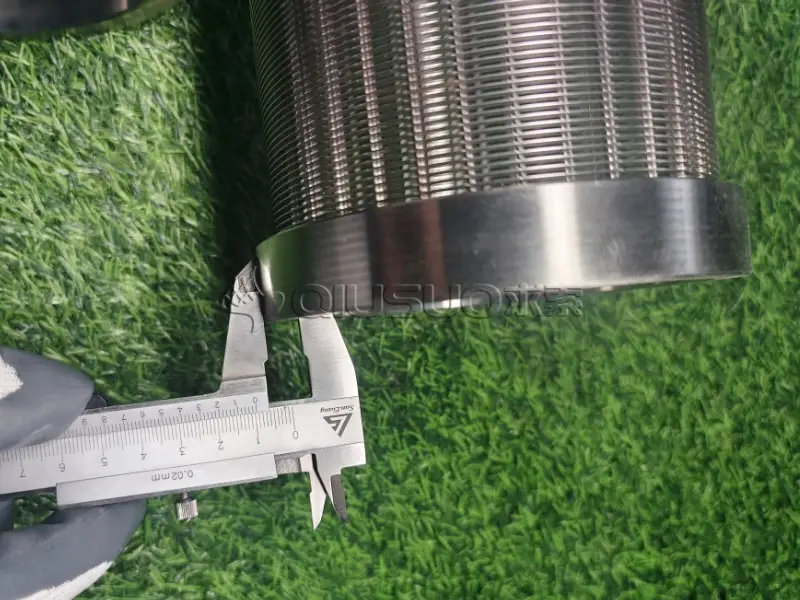

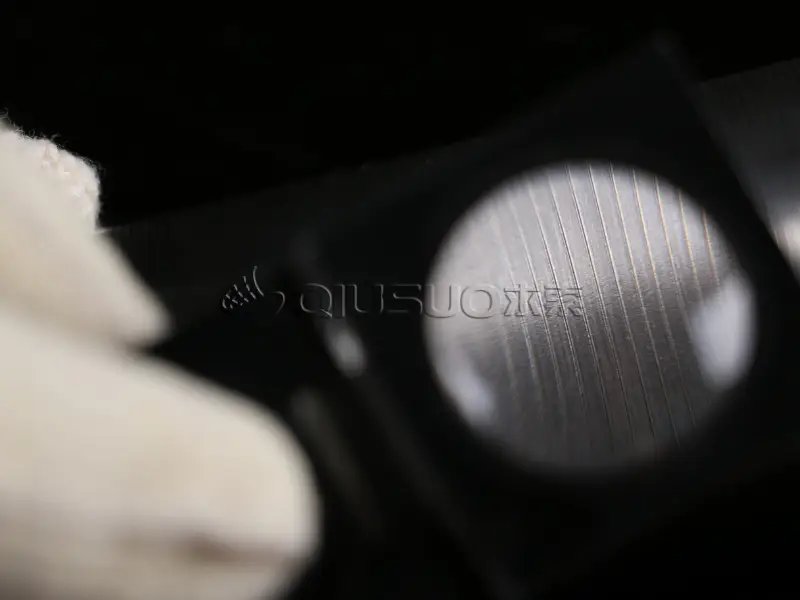

Industrial Filtration

Industrial FiltrationWedge wire products play good filtering and separating performance in various industrial productions. They let projects smoother and cleaner.

- Capacities

- Service

Strong Support

Strong SupportProfessional articles, complete catalogues and efficient RFQ forms let our communication and cooperation more smooth and efficient

- Selection Guide

Selection Guide

Selection GuideFollow our wedge wire selection guide to choose the wedge wire products step by step to save your value time and effort.

- About

About Qiusuo

About QiusuoWe are professional and dedicated in wedge wire products manufacturing and researching. We will help you efficient projects with our qualified products and complete solutions.

- Contact