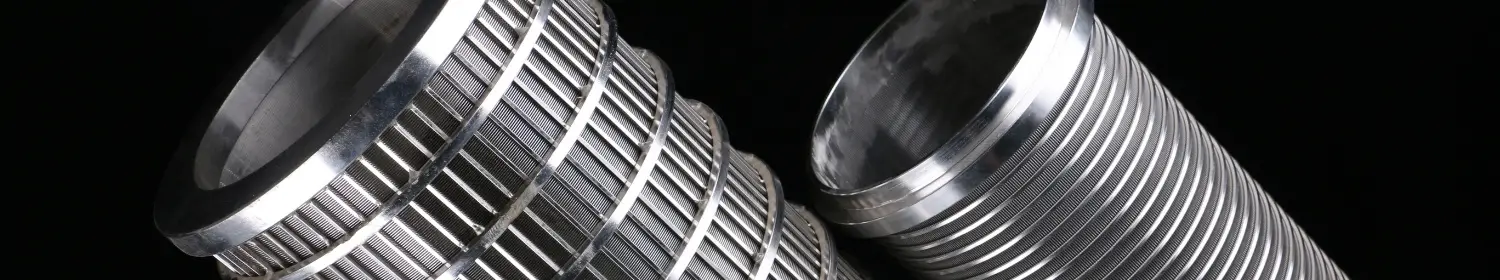

Radial External Type

Radial external wedge wire tubes are composed of axial support profile rods and radial surface Vee wires, which are wrapped around support wires and attached to each other by resistance welding.

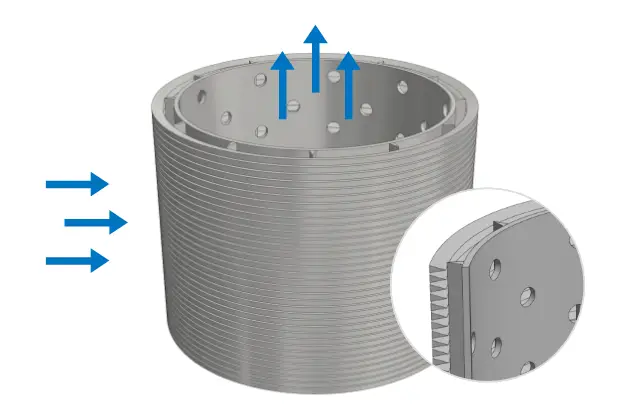

- When the flow direction is from outside to inside (FOTI), the flat side of the surface wire is on the outside of the tube, shown as figure 1-1

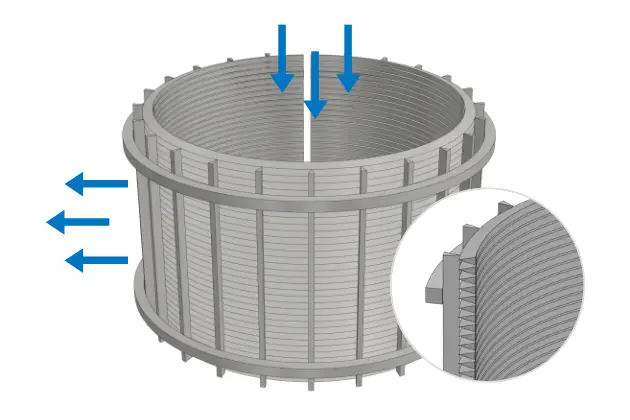

- When the flow direction if from inside to outside (FITO), the flat side of the surface wire is on the inside of the tube, shown as figure 1-2. It is also called reverse wedge wire screen tube.

Figure 1-1 Radial External – FOTI Standard

- Standard type for most applications

- Precision openings

- Economical production

Figure 1-2 Radial External – FITO

- Also named as reversed welding, which radial external surface screen wire’ sharp point outside

- Backwashing

- Inverted circumferential external surface profiles

Radial Internal Type

Radial internal wedge wire types are rolled from flat wedge wire screen panels not continuously spirally wrapped around axial support profiles, that means there are many welding joining points and only flow in one direction (FITO), shown as figure 2.

Figure 2 Radial Internal – FITO

- Smooth internal screen surface

- Facilitates cleaning with an internal axial-movement scraper

- Economical easy for small quantity and any size production

Axial External Type

Axial external wedge wire screen tube or cylinder is rolled from flat wedge wire screen panels and is composed of radial support profile wires and axial surface screen profile wires, which are axial outside the support wire. Because of the flat side of surface screen Vee wires on the outside of the screen, the flow direction of this type is commonly from outside to inside (FOTI), shown as figure 3-1.

Figure 3-1 Axial External – FOTI

- Standard type

- Economical and easy production

- Flat side of wedge wire outside

Axial Internal Type

The axial wedge wire screen tube or cylinder is comprised of surface screen profile wires oriented axially inside of the screen tube and support profiles oriented radially outside of the tube. Because of screen Vee wires on the inside of the screen, the flow direction of this type is commonly from inside to outside (FITO).

There are two types based on the slot and filter size: the first type is rolled from flat wedge wire screen panels, resulting in multiple welding joining points, shown as figure 4-1, while the second type involves the continuous spiral wrapping of support wires around axial surface wedge wires, shown as figure 4-2.

Figure 4-1 Axial Internal – FITO Joint Support

- Smooth internal screen wire surface, ID can be processed, no welding molds limited.

- Economical utility with several welding joining points

- Facilitates cleaning with an internal axial-movement scraper

- The flow moves across the wire edges for effective dewatering

Figure 4-2 Axial Internal – FITO Continuous Support

- Smooth internal screen wires surface, one welding molds suit for one screen ID, higher production costs.

- Without a welding seam, more stronger strength

- Facilitates cleaning with an internal axial-movement scraper

- The flow moves across the wire edges for effective dewatering

Reinforcement Type

Except of figure out the flow direction, structure of screen surface profile wires and support wires, there are also a few common strengthening forms for the wedge wire screen tubes or cylinders.

Reinforcement perforated tube

Reinforcement spiral ribs (flange ring, round steel & square steel)

Reinforcement external ring ribs

Reinforcement external vertical ribs

Reinforcement external ring ribs and vertical ribs

Industrial Filtration

Industrial Filtration Strong Support

Strong Support Selection Guide

Selection Guide About Qiusuo

About Qiusuo