General Questions

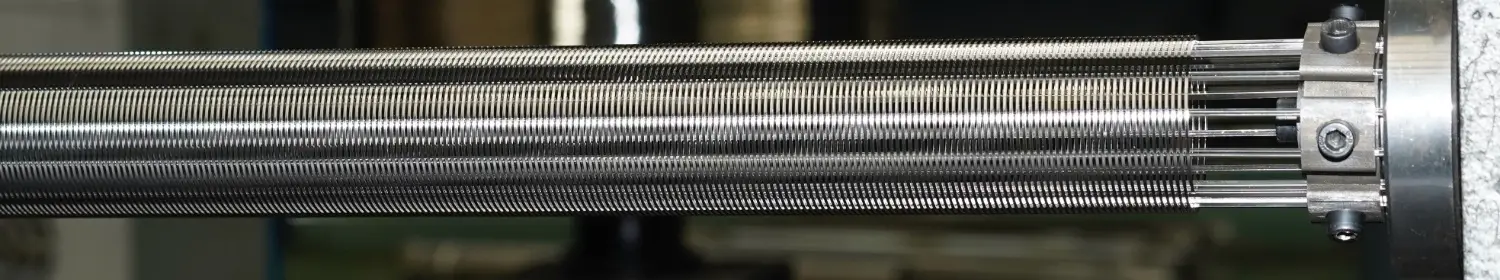

What is wedge wire?

Wedge wire is a type of wire mesh screen characterized by its unique wedge-shaped wires, which provide excellent filtration, sieving, and straining capabilities.

What are the primary applications of wedge wire products?

Wedge wire products are widely used in industries such as water treatment, mining, food processing, and petrochemicals for applications like filtration, screening, and sizing.

How is wedge wire different from other types of wire mesh?

Wedge wire is distinct due to its V-shaped wires, offering precise openings and high strength, making it ideal for demanding filtration tasks.

What materials are commonly used for wedge wire manufacturing?

Common materials include stainless steel, carbon steel, and various alloys, chosen based on factors like corrosion resistance and strength.

What industries commonly use wedge wire screens for filtration?

Industries include water treatment, oil and gas, pulp and paper, mining, and food and beverage.

Features and Specifications

What is the slot opening size in wedge wire products?

Slot opening sizes vary depending on the product and application, ranging from microns to millimeters.

How do I choose the right wedge wire product for my application?

Consult with our experts, considering factors like flow rate, particle size, material compatibility, and environmental conditions.

What is the maximum length of wedge wire screens available?

Wedge wire screens can be manufactured in lengths tailored to your specific requirements.

How is the strength and durability of wedge wire products ensured?

Our products undergo rigorous quality control and testing to meet industry standards and ensure durability.

Are wedge wire products resistant to corrosion?

Yes, our stainless steel wedge wire products are highly corrosion-resistant.

Installation and Maintenance

What is the maintenance and cleaning process for wedge wire products?

Maintenance typically involves backwashing, brushing, or chemical cleaning, depending on the application.

How do I install and maintain wedge wire products for optimal performance?

Detailed installation and maintenance instructions are provided with our products to ensure optimal performance and longevity.

What is the expected lifespan of wedge wire screens?

With proper maintenance, wedge wire screens can have a long lifespan, often exceeding 10 years.

Customization and Special Applications

Can wedge wire products be customized to specific dimensions?

Yes, our wedge wire products are highly customizable to meet your exact specifications.

Are wedge wire screens suitable for high-temperature applications?

Yes, we offer specialized materials that can withstand high-temperature environments.

Do wedge wire screens come in different shapes, apart from flat panels?

Yes, we offer various shapes such as cylinders, cones, and baskets to suit different applications.

What are the advantages of using wedge wire screens for water treatment?

Wedge wire screens offer high efficiency, durability, and low maintenance, making them ideal for water treatment processes.

Are wedge wire screens suitable for offshore and marine applications?

Yes, our corrosion-resistant wedge wire screens are commonly used in offshore and marine environments.

Can wedge wire products be used for architectural and decorative purposes?

Yes, wedge wire screens can be used for architectural and decorative applications, offering a unique and modern aesthetic.

Technical Support

Do you provide technical support and guidance for selecting wedge wire products?

Yes, our team of experts is available to assist you in selecting the right wedge wire products for your specific needs and applications.

Company

What is the history of your company?

Our company was founded in 2016 and has since grown to become a leading manufacturer of wedge wire products.

Are you an ISO-certified company?

Yes, we are proud to be ISO 9001 certified, demonstrating our commitment to quality management.

Can you provide references or case studies showcasing your work?

Absolutely, we have a portfolio of successful projects and satisfied clients. Please

contact us for references or case studies.

How do you ensure the quality of your products?

We have strict

Quality Management System and maintain strict quality control standards and rigorous testing processes to ensure the highest quality in our products.

Industrial Filtration

Industrial Filtration Strong Support

Strong Support Selection Guide

Selection Guide About Qiusuo

About Qiusuo