Working Principle of Wedge Wire Screen Tubes in Radical Reactors

Catalytic reforming is an important process for improving gasoline quality and producing petrochemical raw materials. Catalytic reformer is one of the most common devices in modern petroleum refineries and petrochemical catalytic reforming joint enterprises. According to the flow direction of oil and gas in the reactor, it is divided into axial reactors and radial reactors. Radial reactors are widely used in modern reforming units.

Radical reactor internal structure

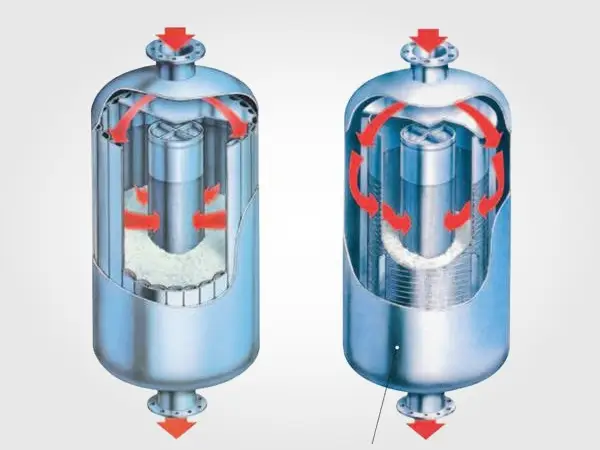

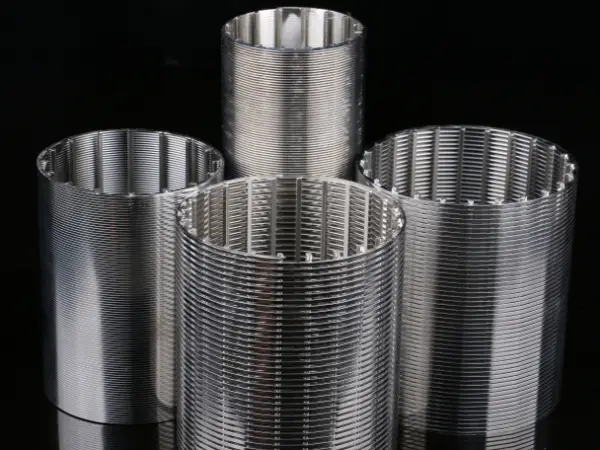

The existing radial reactor is equipped with a gas distribution device and a gas collection device, which are respectively installed in the center and around the reactor. The gap between the two is filled with catalyst to form a catalyst bed. There are two kinds of wedge wire screen tubes in radical reactors: scallop wedge wire screen tubes and cylindrical wedge wire screen tube. The devices installed around the reactor are scallop wedge wire screen tubes (flat tubes). According to the flow direction of the gas, they respectively serve as the flow diversion channel or the flow collection channel of gas respectively. The device installed in the center of the reactor is a cylindrical wedge wire screen tube and the bottom of the wedge wire screen tube is connected to the outlet of radial reactor. When the reactor is working, the raw materials enter from the inlet at the top of the reactor, and a series of reactions occur under the action of the catalyst. The gas will be collected in the cylindrical wedge wire screen tube and transferred to the next reaction stage.

Working principle of radical reactor

Outside wedge wire screen tube

Wedge wire screen tubes for radical reactor

Catalytic reforming is an important process in the refining and petrochemical industries. In the actual catalytic reforming reaction, many unexpected situations may occur. For example, in the case of sudden shutdown, the catalyst will move toward the scallop wedge wire screen tube where the gas is accumulated in the reactor. The scallop tube is subjected to a large external force, which may lead to instability and deformation. Therefore, we must choose high quality wedge wire screen tubes to ensure their compressive strength, flatness, verticality and other factors to improve the catalytic reforming effect.

Industrial Filtration

Industrial Filtration Strong Support

Strong Support Selection Guide

Selection Guide About Qiusuo

About Qiusuo