Custom Wedge Wire Basket: Seawater Corrosion Solution

Time: Nov. 25, 2025

Scene: Seawater environment

Region: America

Our long-term client approached us with a new project requiring high-performance basket screens for use in a seawater environment. Since corrosion resistance was critical, the customer specified that all components, including the frame, screen panels, U-plates, and all perforated parts, must be made from SS2507.

The customer provided an initial concept drawing, which depicted a circular assembled structure. Based on the project requirements, our engineering team worked closely with the client to refine details such as the number and orientation of the screen panels, the type and layout of perforations, and the structural design of the frame. After several rounds of technical communication, we submitted the final drawings for confirmation before proceeding with production.

As part of our standard procedure, every batch must undergo a full quality inspection before shipment. During the first trial fabrication, our QC team identified that the position of one flange hole did not meet the specified tolerance. To ensure compliance with the confirmed drawings, we promptly re-manufactured the affected part. The revised components were completed within two days and passed inspection successfully.

Through this project, we once again demonstrated our commitment to precision manufacturing, rapid technical response, and reliable quality.

Basic Products Specification

- Product: Wedge wire basket

- Material: Super duplex steel 2507

- Size: O.D. 2300 mm

- Working wire: 2 × 3 mm

- Support rod: 3 × 4.5 mm

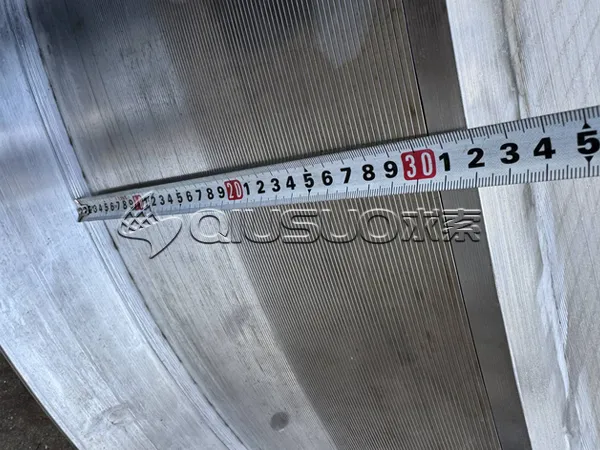

- Pitch: 20 / 30 mm

- Slot: 0.25 mm

- Side tube: 25.4 × 25.4 × 6.35 mm

- Bottom tube: 76.2 × 50.8 × 6.35 mm

- Top ring: 12.7 × 50 mm

- Quantity: 1 pcs

Finished Products & QC Photos

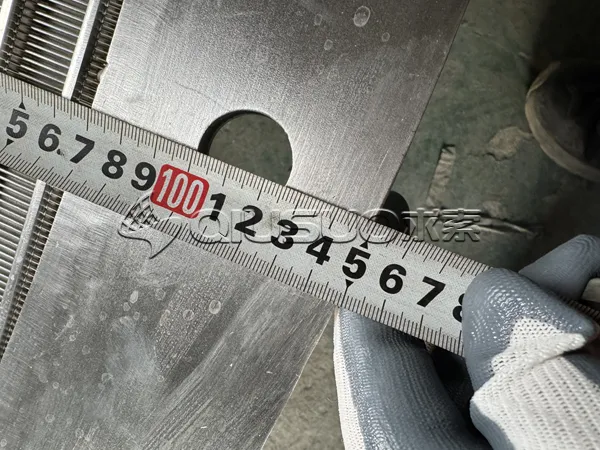

27.75 mm support rod spacing

101.67 mm connection outer diameter

97.84 mm connection inner diameter

25 mm frame hole diameter

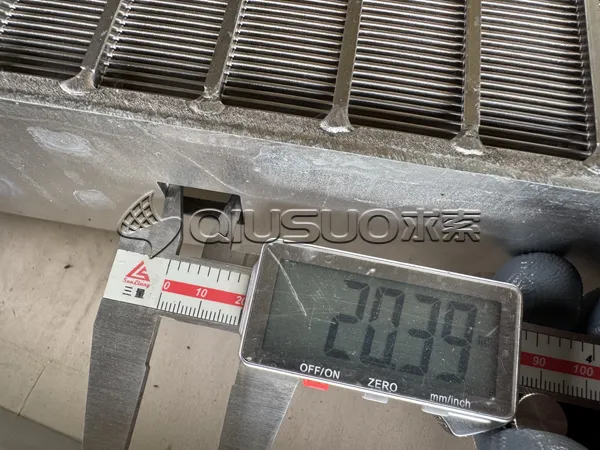

20.39 mm mounting hole width

3.1 mm support rod back width

Wedge wire basket packaging

Industrial Filtration

Industrial Filtration Strong Support

Strong Support Selection Guide

Selection Guide About Qiusuo

About Qiusuo