Why Does Stainless Steel Wedge Wire Screen Panel Need Cleaning?

The material we use to make wedge wire screen panels is stainless steel. Proper maintenance can extend the lifespan of products and maximize their value. How to clean and maintain stainless steel wedge wire screen panels? Here is a brief introduction for you to help you learn more about stainless steel products cleaning and maintenance.

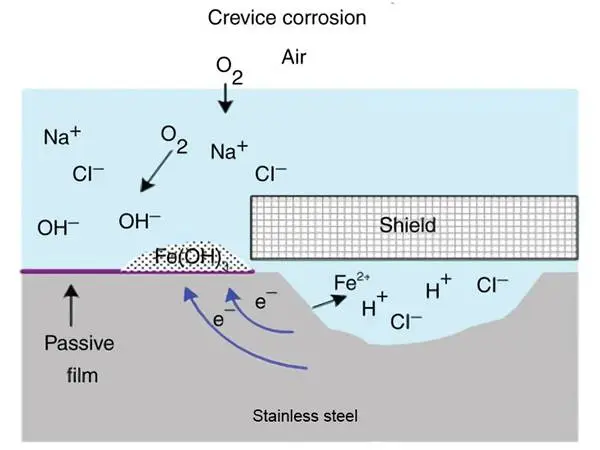

Many people think that stainless steel will never rust. In fact, stainless steel does have good corrosion resistance; however, if we don't maintain it properly, it will also rust. The reason is that a passive film is formed on the surface, which exists in the form of more stable oxide in nature. In other words, stainless steel is oxidized according to different service conditions and different oxidation levels. This phenomenon is often called corrosion.

Stainless steel wedge wire screen panel

Stainless steel wedge wire screen panel surface corrosion

In the passive film on the surface of the stainless steel wedge wire screen panel, a pitting reaction is formed due to the self-excitation reaction, which results in the formation of small holes. In addition, chloride ions are close to each other, forming a strong corrosive solution, thereby accelerating the corrosion reaction rate. There are still intergranular corrosion cracks in the stainless steel wedge wire screen panels. All cracks will damage the passive film on the wedge wire screen panel. Therefore, the surface of stainless steel must be cleaned regularly to maintain its gorgeous appearance and extend its service life.

Principle of crevice corrosion

Cleaning stainless steel wedge wire screens panel is a complex task. The following cleaning steps are recommended:

- You need to prepare soft towels or wipes.

- Choose to buy professional stainless steel detergents, such as weak detergents, organic solvents or special detergents.

- Wipe the surface of the stainless steel wedge wire screen panel with a soft towel and wipe it repeatedly with a slightly damp towel until there are no obvious marks on the surface.

- If the surface of stainless steel wedge wire screen panel is dusty, you can add alcohol, weak detergent or organic solvents (ether, benzene) in warm water, and wipe it repeatedly with a slightly wet towel until there are no marks on the surface.

- If the surface of the stainless steel wedge wire screen panel is contaminated by oil or lubricant, wash it with neutral detergent, ammonia solution or special detergent. And then wash it immediately with clean water. Finally, wipe it with a clean towel.

The long-term accumulation of stains will increase the difficulty of cleaning. Therefore, a good habit of cleaning the stainless steel wedge wire screen panels regularly should be developed to reduce the difficulty of cleaning. In addition, since the surface of the stainless steel wedge wire screen panel is easily scratched by metal, be careful not to use steel balls or other similar tools to clean the surface.

Industrial Filtration

Industrial Filtration Strong Support

Strong Support Selection Guide

Selection Guide About Qiusuo

About Qiusuo