Water Intake Screen Help Nuclear Power Plants Filter Clean Waters

As we all know, water intake screen is the first safeguard of clean waters. But what the functions of water intake screen in the nuclear power plants?

Industry Background

Nuclear energy is an environmental-friendly energy source and plays an ever-increasing role in modern society. With over 30 years of development, nuclear energy construction and production has been grown and prospered in China. Nuclear power generation requires a large amount of water drawing from the ocean; therefore, water quality treatment is crucial to the success of nuclear energy production. Seawater can be used for power stations only after repeated chemical and physical treatment including adsorption, sedimentation or blocking to purify water quality. The way of blocking is to make water pass through the filter material while keeping bulky impurities out, thereby getting cleaner water for the power station. As a new type of structural filter material, wedge wire are increasingly used in nuclear power plants due to its great filtration precision, high structural strength and easy backwashing performance.

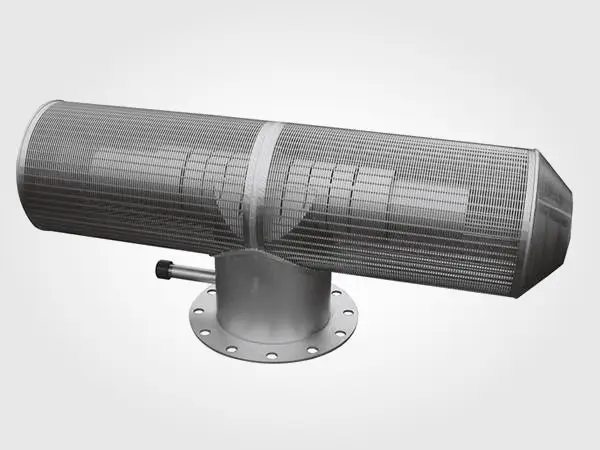

Wedge wire screen serves as water intake screen.

Wedge wire screen in water intake.

Working Principle

Until know, water intake screen has formed a series of standardized products, which are widely used in petrochemical, food and other industries. These provide reference for its promotion in nuclear power plant.

The application of wedge wire intake screen in nuclear power plant facilities is to filter water from lakes, rivers, streams and reservoirs. Screens can be placed far away from the shore for better water quality and lower concentrations of marine life and debris. When the pumps draw waters from water, the water with impurities passes through the water intake screen, clean waters are pumped into the pipes and the debris and aquatic life are filtered outside the pipe.

Different Intake Water Filtering Materials Comparison

At present, the most commonly used filter materials in nuclear power plants include woven metal screens, metal powder sintered screens and laminated screens. The following table is a comparison table of wedge wire screen and filter materials commonly used in nuclear power plants:

Table1: Different Intake Water Filtering Materials

| Item |

Name |

Comparison |

| 1 |

Woven wire screen |

It has a large flow area; however, it filters large impurities only. |

| Wedge wire screen |

It is suitable for high precision filtration. |

| 2 |

Metal powder sintered screen |

Curved internal holes makes the screen cannot be cleaned when impurities entering the inside of the filter element and needs to be replaced regularly. |

| Wedge wire screen |

Under the same filtration accuracy, its backwashing performance makes it free from regular replacement and maintenance. |

| 3 |

Laminated screen |

It wears seriously under impact of water flow and has a short service life. |

| Wedge wire screen |

Filtration accuracy, structural strength and pressure drop resistance meet all requirements |

Through reviewing the above sheet, we will find that the wedge wire intake screen has better performance and efficiency than other filter materials.

Although the application of intake screens in nuclear power plants is still in the stage of rapid development, its unique structure and characteristics makes it been widely used in various nuclear power plant projects under construction.

Besides, its safety and reliability have been verified repeatedly in practice. The process of water intake screen keeps improving. The wedge wire intake screens are sure to grow faster and strong with the constant improvement of wedge wire screen process and the rapid development of nuclear power.

More Information

If you are interested in our water intake screen, just contact our specialist for help or you can browse the structures and specifications of water intake screen for more choice.

Industrial Filtration

Industrial Filtration Strong Support

Strong Support Selection Guide

Selection Guide About Qiusuo

About Qiusuo